| Modification : | |

| E-clip Modification to front wheel hub | |

|

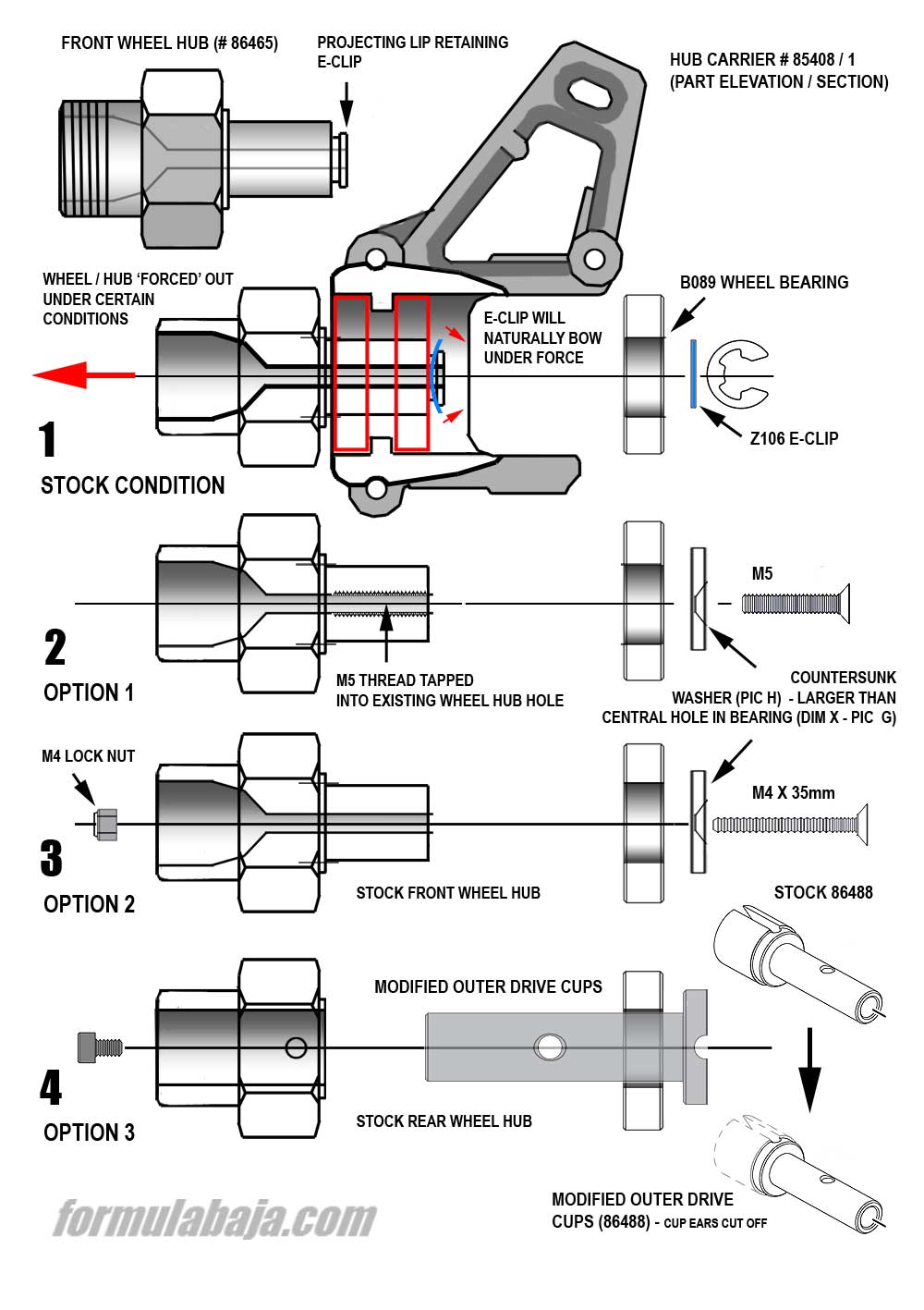

Under

certain running conditions, when excessive force is placed upon the

front wheel, eg impacts from extreme landings, cornering etc, the e-clip

will tend to 'pop' off, releasing the front wheel with hub intact (diagram

1 shows stock e-clip connection). The

following are just two of the numerous options of this simple

modification that can be carried out to prevent wheel loss. |

|

|

|

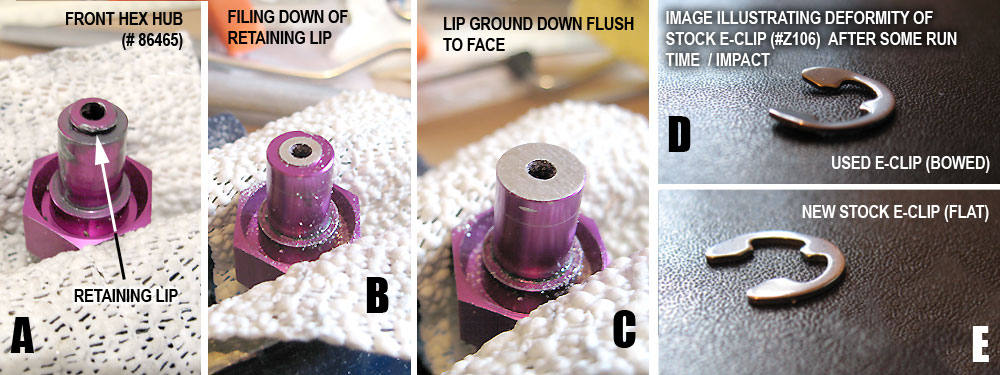

| Option1

(pic 2, above) - shows an M5 thread tapped into the existing hub

hole, following the removal of the projecting retaining lip (pic A,

below). No specail tools are required to tap the existing hub -

simply use a steel M5 bolt and T allen wrench to gradually and carefully

tap the softer aluminium. After every turn and a half, remove the screw to

ensure a good tap, then re-screw and proceed to the desired depth. Option 3 (pic 4, above) - shows how a stock rear hub can be modified and used as an alternative to a front hub. Here the ears of the outer drive cup are cut, and the area ground flat to form an integral head as opposed to using a washer and screw system. |

|

|

|

|

|

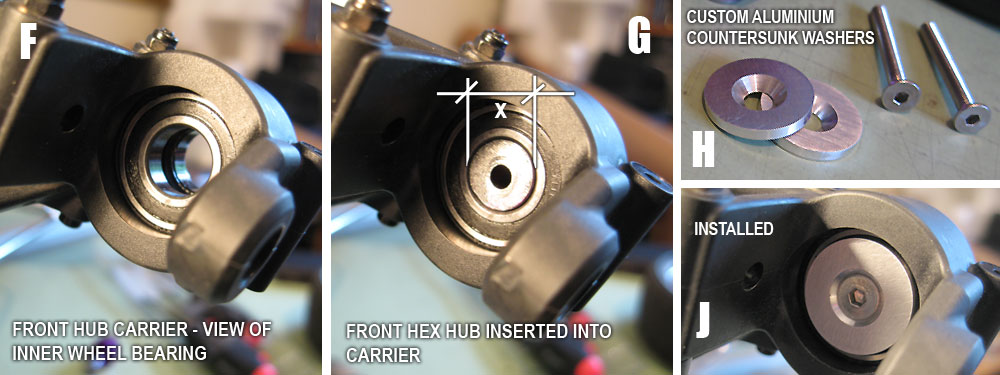

| The

above pictures can be used to illustrate both options 1 & 2. It is important to first check the clearance available between retaining lip and the edge of the ball joint. This dim will vary, and will be instrumental in choosing how to proceed and what fixings will be most suitable. In this example the final projection from the face of the inner bearing, including washer, plus screw head (countersunk, button head or otherwise), could not exceed the original retaining lip projection. Whatever option and fixing method is chosen, it is recommended to check for free movement while using the radio to turn steering at full lock, left and right, simultaneously moving the suspension through its full motion. Aftermarket (billet) front arms* will have different tolerances to those of the stock plastic arms. Some grinding to the ball joint or further modification to the screw / washer assembly may be required. The use of circlips

/ washers can provide a good midway

solution, providing a stronger hub connection, but with 'release' in

extreme conditions (see further reading). |

|

| Pic H - custom aluminium countersunk washers courtesy - Skaa63 | |

Further Reading - HPIBajaForum thread Get rid of those front hub E-Clips! Tutorial - GeneralG Front Hex Improvement - Karg HELP!! can't do eclip mod!! - Scoobysting |

|

| Rev 1 - 7 Aug

2008 Rev 2 - 19 Dec 2010 |

|