| Modification : | |

| Gas Cap Vent Mod | |

|

The stock gas cap vent hole (hidden within the 'R' of the raised

lettering spelling '2-STROKE') is prone to leaking fuel, which attracts

dirt and can easily become clogged. The leaking fuel of course leads to

messy maintenance issues and excessive and undesirable fuel odours.

However, once the small vent hole is blocked, air is restricted from

freely entering the gas tank to replace the volume of fuel used by the

engine. As such, negative pressure (vacuum) can build within the tank

and affect the flow of fuel from the tank to the carb / engine, and

ultimately affect performance. There are of course a number of diy and

aftermarket options available to help solve these potential issues. The

principles adopted in each are similar, to allow the gas tank to breathe

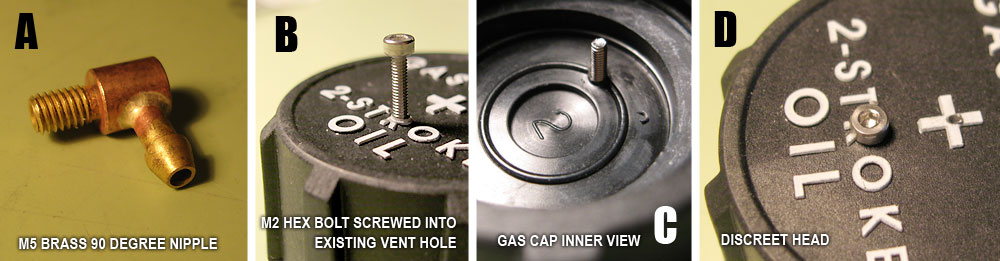

and ideally prevent fuel leakage. This option illustrates the use of an M5 90 degree brass nipple fitting (pic A), a length of 450mm 3mm ID fuel tube (petrol / gasoline spec.) to serve as the breather line, an M5 locknut, a small o-ring and a readily available fuel tank breather vent (the type used on petrol chainsaws / strimmers). |

|

|

|

| By slightly enlarging the existing vent hole, an M2 hex bolt can be screwed into the plastic (pic B / D), thereby sealing what will shortly become a redundant vent under this mod. Any type of suitable screw or set screw can be used to terminate the existing vent. Alternatively, epoxy or some other appropriate sealer can be used. | |

|

|

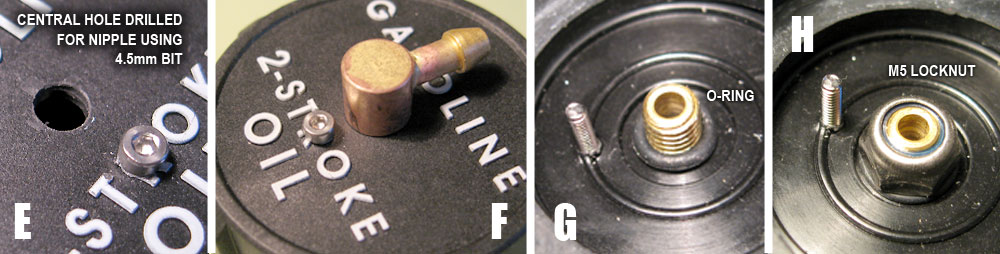

| Using a 4.5mm drill bit, a hole is made to receive the brass fitting (pic E). A pilot hole is always a good idea (pic D). The raised cross can be sliced off using a sharp blade to give a flush finish for the fitting. Once the nipple fitting is seated, the o-ring is slipped on and the M5 locknut gently screwed down, just snug enough to squish the o-ring. The final direction of the nipple can be adjusted to suit, but forward facing seems to work best with the gas cap thread and a 5B body shown here. | |

|

|

| Retaining the stock gas cap inners will avoid the need for a large o-ring, and will help restrict fuel freely reaching the nipple inner opening and entering the breather line. | |

|

|

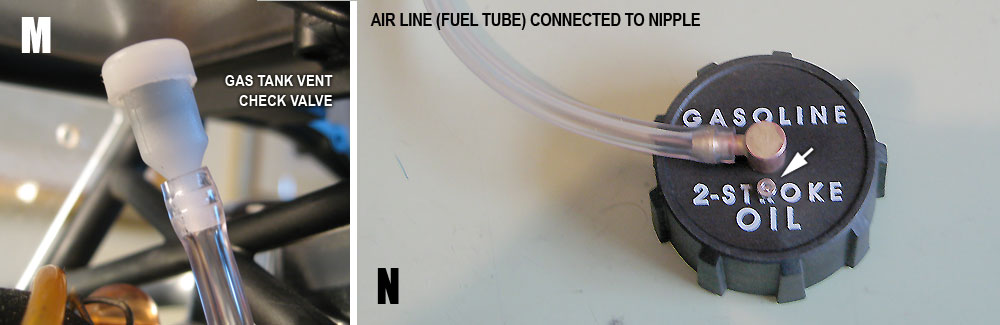

| Breather line connects to both vent and nipple. Depending on the flexibility of fuel tubing used, an ID of 3mm may be a little difficult to slip onto the nipple and vent. Warming the ends of the tubing on a hot surface such as a radiator will make them supple and ease the installation greatly. | |

|

|

|

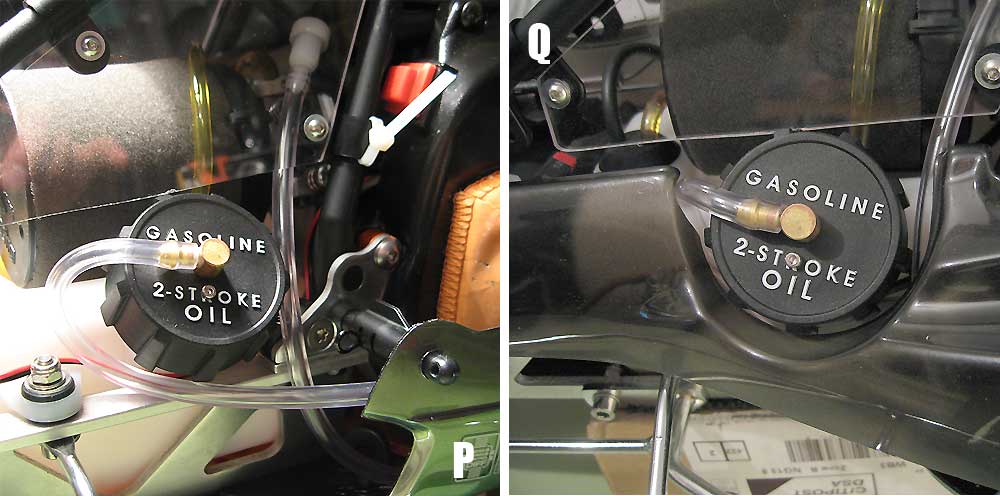

A length of tubing 450mm will allow the check valve to sit adjacent the

air filter/carb, protected inside the window, and also form a loop at

the bottom of the side pods (pic P). If fuel happens to enter the tube

(eg due to a faulty valve), the loop will help prevent any or excessive leakage

whether Baja is on its tyres or roof. NOTE: Two types of fuel tank breather vents were tested - the type installed here did not leak or allow fuel to move into the breather line from the tank when the Baja was inverted and shook, with engine idling, high RPMs, and engine off. Any vent used should allow air to move in, but prevent fuel exiting, ie a one way valve. The aluminium type (motorcycle) gas tank cap breather vent (pic R - shown next to the plastic type used here) - which is also described as a one way valve, allowed fuel to readily leak when inverted and put through the above test procedures. Of course not carried out under laboratory conditions, it should be noted that types of the same vent can vary greatly in function. It is highly recommended to test any proposed breather vent. |

|

|

|

| An easy mod with a discreet finish. Gas cap is easily removable for refuelling, a cheap gas cap is modified in favour of a relatively expensive petrol tank, and of course can be used on Baja to Baja. | |

| Links - Many threads on this

subject, here are a handful... Fuel tank vent mod Gas Cap Vent Modified Gas tank vent Rubber tube out of gas cap? |

|